Hydraulic System For Aircraft - Members MORE LEARN MORE - Download MORE Become a Pilot - CLICK HERE

As the plane gets bigger, more and heavier parts need to be moved. A heavy chassis has increased the force of gravity, a flap shield reaches 200 skid resistance, or the braking system has to generate a lot of force against the tires - all these require a strong force behind them.

Hydraulic System For Aircraft

The Cessna Citation Mustang has one of the simplest hydraulic systems. A single electric pump delivers power when needed and controls just two systems, the chassis and brakes.

Integrated Hydraulic Systems

These functions are usually attributed to the hydraulic system. As aircraft get heavier, it is common for more systems to become hydraulic "clients". So while Cessna Citation Mustangs and Embraer Phenom 100s only need hydraulic power for the landing gear and brake systems (using electric motors for other parts like flaps), the high-powered CJ also uses hydraulic power for flaps and brakes. and the Phenom 300 adds more spoilers, pushrods and handlebar additions to the list.

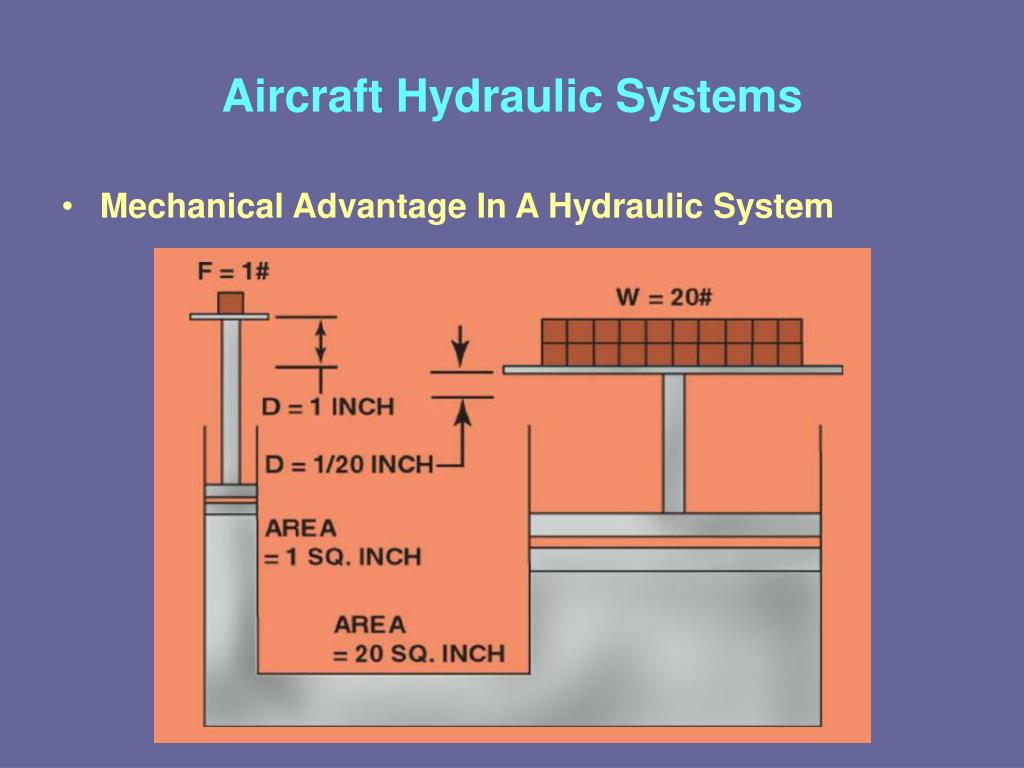

All hydraulic systems work on a common principle: a disposable hydraulic fluid is used as a means of transferring power from the pump to the equipment being moved. Some systems store the hydraulic fluid at high pressure until it is needed, while others pressurize the fluid only when the customer requires it. How fast? Thank you very much - usually about 3,000 pounds per square inch (psi), or about the atmospheric pressure of an ocean a quarter of a mile underground.

Smaller aircraft have less hydraulic requirements and usually pressurize water through an electric pump. Depending on the system, the pump can be cycled on and off to maintain the pressure at the desired level, or opened only when one of the customers requires pressure. In any case, it's common to have some kind of collection on the side of the pump's auxiliary system. A hydraulic accumulator can be thought of as a hydraulic "battery" that can be pumped slowly by the pump for rapid discharge when the pump cannot maintain pressure requirements.

The accumulator usually consists of a high-capacity canister and a reduction slide. On one side of the distributor is a quantity of trapped gas, often nitrogen. As the hydraulic pressure on the other side drops, the gas gets more and more compressed and tries to push back and split from thousands of energy units. If the pressure in the hydraulic system drops below the pressure in front of the accumulator, the accumulator will push water, temporarily increasing the power of the hydraulic system.

Aircraft Hydraulic System Market Size, Growth

Larger aircraft have greater and greater demands on hydraulic systems, which require more pressure than an electric pump can produce. These aircraft use a hydraulic motor driven by an engine. Connected to a high speed motor, the pump rotates every time the motor rotates. Again, there is variation in system design, with some manufacturers choosing to keep the system at high pressure at all times, while others choose to circulate the water at low pressure while the customer is using it. The 525 Citation mixes two types of pumps, with most hydraulic systems receiving power from two pumps driven by the engine, while the brakes are supplied by a completely separate hydraulic system with an electric pressure pump.

However, the pressure that builds up will go to the hydraulic system in addition to the fluid being sent to the brake system, a way to change the pressure while traveling. High-pressure water enters the motor and pushes the sliding part, which is finally connected to the moving part of the plane.

The actuator is designed to be double-sided: press one side, for example, to raise the flaps, or the other side to lower them. The position of the customer's control system is moved, usually by electricity, to bring speed to the operating side of the road.

During normal operation, the role of the aircraft and the hydraulic system is minimal. It is common for the pilot to have no direct control of the hydraulic system at all, except to pull the throttle lever to shut off the hydraulic pump. Abnormalities are often caused by the system not providing enough pressure due to a pump failure (in the case of a single-pump system) or water leakage in the case of a multi-pump system. Because critical hydraulic components such as the chassis and brakes have a reversible mechanism of action, hydraulic system failure is considered a rare event rather than an emergency.

Part Of A Hydraulic System In An Airplane In Alliance, Ohio Circa 1942 1945

But that doesn't mean it shouldn't be taken seriously. The braking system in particular is known for its touch and is very much under the pilot's control, easily targeting the tires. This is because they are manual and often do not provide sliding or wheel locks.

On the downside, hydraulic failure is often associated with a combination of braking difficulties: loss of stopping power and soil erosion, for example, to create and maintain friction between tire and road. Alternatively, if the brake system is not damaged, the flaps may be, and since flap recovery is not a function of normal airplanes that do not have smooth landings and high top speeds. For these reasons, hydraulic failures usually require a much longer investigation than usual. Hydraulic systems can be a challenge for design engineers due to the many obstacles they face when designing a hydraulic or hydraulic system. Program. Hydraulic technology in aircraft control first saw its foundation during World War II, when hydraulics were introduced to control the secondary control system. However, as aircraft performance and capabilities increased, hydraulics began to play an important role in the critical and safety functions of airplanes, helicopters, and high-performance military aircraft. Commonly used hydraulic functions in commercial aircraft include forward flight controls, flap/flap actuators, landing gear, front wheel steering, reverse, spoilers, elevators, cargo doors, and emergency hydraulics.

Some of the hydraulic systems used in modern aircraft include forward flight controls, flaps/slats, landing gear, nose flaps, retractors, spoilers, wings, cargo doors, and emergency power thrusters. Military aircraft also use hydraulics for gears, gun doors, and hydraulically driven heat pumps. Factors to consider in aircraft include pressure conditions (both internal and ambient), temperature extremes, weight, speed, materials, reliability, watertightness, leakage, cost, noise and density.

Air pressures in aircraft hydraulic systems are very high compared to most industrial applications, typically between 1,500 and 2,000,000 psi. moved to 5,000,000 psi). High-speed power comes from aerodynamic considerations and the need for less weight, as the engines can generate more power and heat from a smaller envelope.

Why Are Aircraft Hydraulics So Important?

Not only does the system have to deal with expected changes in ambient temperature occurring around the world, but the surface of the plane also experiences sub-zero temperatures. Most commercial systems are designed to withstand temperatures between 65° and 160°F, while military aircraft can operate between 65° and 275°F.

Aviation water has a relatively low (compared to industrial water) resistance to cold and heat - in other words, it is low. Additionally, this water must be extinguished, which is a major concern when the nearest fire department may only be five miles away, but five miles up the mountain. One of the unique properties of aircraft hydraulic fluids is that they remain liquid at -65°F, i.e. i.e. the temperature at which water-based oils and greases will freeze. The best water choices for the air industry are:

MIL-H-5606 - was first introduced over fifty years ago and is still used on many aircraft. Used in commercial aircraft and most US Air Force aircraft, it is highly flammable and is believed to be responsible for the loss of at least one military aircraft to fire.

MIL-H-83282 - First used by the Air Force in 1982. and the US Navy in 1997, is less flammable than 5606, but especially at lower temperatures. MIL-H-83282 assumes a minimum operating temperature of -40°F and is used by all Navy aircraft.

Large Aircraft Hydraulic Systems

MIL-H-87257 - This new fluid is used in C135, E3 and U2 aircraft; It is less flammable than 5606 (similar to 83282), but its low temperature resistance allows it to be used down to 65°F.

Skydrol and Hyjet - These alkyl phosphate ester fluids are used in commercial aircraft and are less flammable than the military fluids described above. Maximum temperature

Aircraft hydraulic system components, hydraulic test stand for aircraft, hydraulic system failure aircraft, basic aircraft hydraulic system, aircraft hydraulic system, aircraft hydraulic system design, aircraft hydraulic system schematic, aircraft hydraulic system pdf, aircraft hydraulic fluid, hydraulic system of aircraft, aircraft hydraulic oil, hydraulic system in aircraft

0 Comments